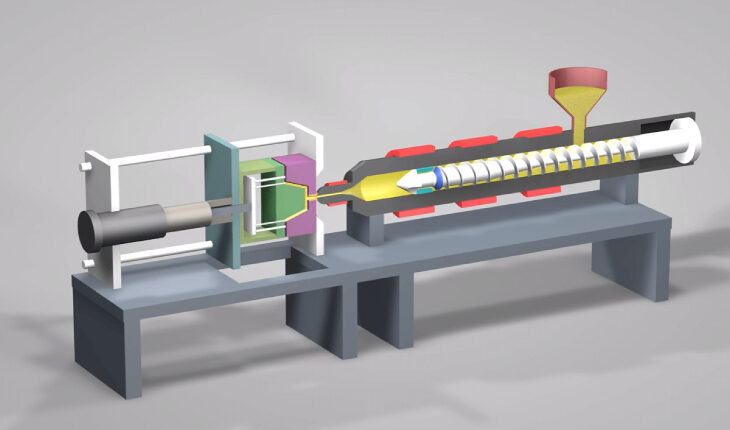

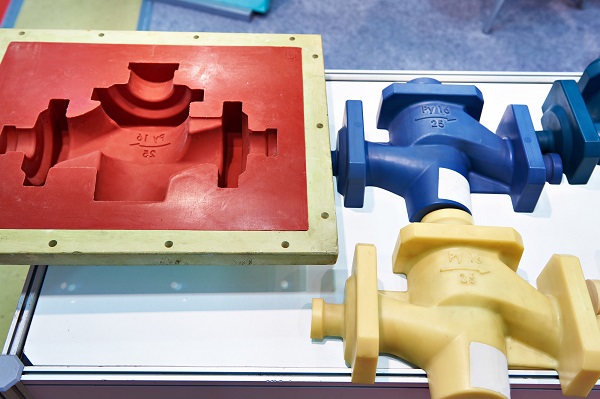

What Is Injection Molding?

Injection moulding is an industrial manufacturing method that allows the production of parts in large volumes. Injection moulding is usually used as a huge production method in the manufacturing of many identical items. The injection moulding materials can range from different metals, confections, elastomers and glasses, etc. However, injection mould manufacturers in India uses injection moulding with thermosetting and thermoplastic polymers. Injection molding companies make various products such as remote control casings, bottle tops, syringes, etc. There are different injection molding processes such as die-casting, metal injection molding, cube moulding, etc.

Benefits Of Injection Molding

Here are some of the major benefits of the injection molding process.

- Ability To Produce Detail Parts

With a scientific molding approach and the right tool design, injection molding helps manufacture detailed plastic parts in huge volumes without any deviation. The key behind this consistency is the right analysis techniques and the appropriate data collection, combined with the service of experienced engineers. In addition, Specialization is much-needed to develop and document the molding specifications and settings. When these are done correctly, it leads to impressive details.

- Efficiency

When the manufacturer works with an experienced injection molding partner, the former gets the advantage of experiencing the efficiency of the molding team, who have decades of experience in designing and manufacturing the parts. With efficiency, more quantity of plastic molds can be manufactured within a short time.

- Enhanced Strength

Strength is one of the major factors required in the production of a plastic injection mold part. The mold designer needs to know whether the product should be flexible or firm to adjust the integrating gussets. Plastic injection molding allows the usage of fillers in the molds. These fillers reduce the density of the plastic and offer great strength to the part.

- Ability To Use Different Types Of Plastic

Injection molding can use different types of plastics simultaneously. Sometimes complex part designs need other components made of various materials. It may seem like a simple process; however, combining plastics safely is extremely complicated work. With the help of con-injection molding, different plastics can be used without any injury risks.

- Saves Cost

Injection molding manufacturing is an automated process. This process is mostly performed by robotics and machines, and a sole operator controls these. Since it is an automated process, it helps in reducing manufacturing costs and overhead costs. In addition, it will also reduce the labor force and thus, a huge part of manufacturing cost can be saved.

- Fast

With injection molding, cycle times can be improved, and it will between 10-30 seconds for each cycle. Such a molding process can produce huge volumes of parts per hour. However, this depends on the impressions that are in your tool.

- Multiple Finishes

Usually, injection-molded parts will have a smooth surface finish close to the expected final look during the production itself. However, having a smooth appearance might not be good for every application. With injection molding, surface finishes can be done depending on the chemical and physical properties of the plastics used in the manufacture.

- High-output Production

A consistent process is required to achieve designs for complex plastic parts. With injection molding, one can ensure that the quality is continuously consistent as the same mold is used for each part.

- Color Control

With injection molders, one can get the desire coloration by aligning plastics, biocompatibility, and additives. Overmolding will be the best solution if a product requires multiple colors.

- Less Wastage

When in need of a huge-volume injection molding partner, one must consider the wastage that can happen. During the injection molding process, there is a huge chance of generating excess plastic. With eco-friendly plastic injection molding, one can minimize wastage.

How Do Injection Molding Affect The Economic Growth

The impact of injection molding is improving along with the advanced technology, which results in maximum efficiency. As per studies, the injection molding market will reach an overall value of $170 billion in the coming years. With innovations, environment-friendly practices, a strong economy, and advanced technology, the plastic injection molding industry is becoming more and more successful. Continue Reading